Photocatalyst

Photo Catalyst

Photo Catalyst

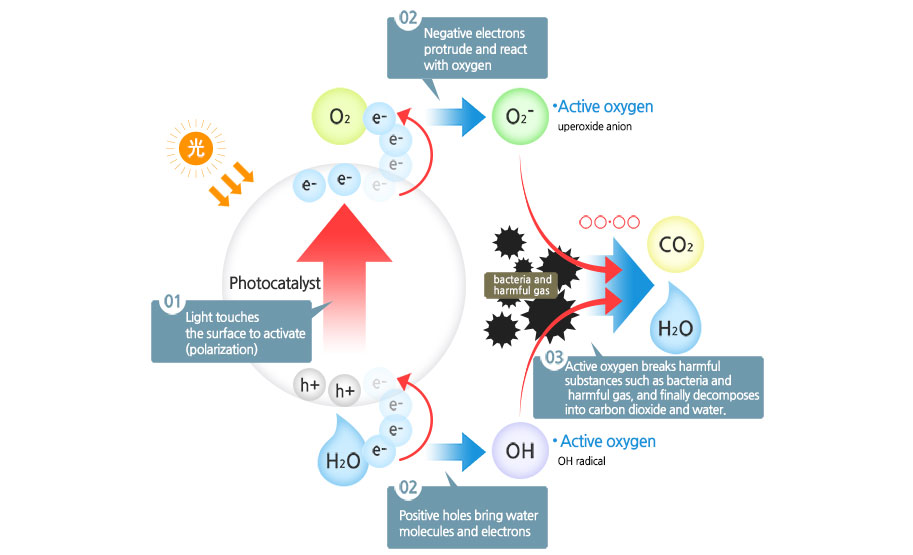

- • It refers to substances which induce photo-chemical reaction, and semiconductors/pigments/chlorophyll are a type of photo catalyst. The photo-chemical reaction induced by the semiconductor material titanium dioxide, TiO₂, was proven by a Japanese scientist in 1967, and it began to be utilized as a basic technology contributing in resolving environmental issues.

- • Titanium dioxide has the property of oxidative decomposing harmful substances (contamination removal, antibacterial, deodorization effect), and its ultra-hydrophile property (property of not forming water drops when surface is damped) is utilized to create glass, tile, cleaner, air purifier, refrigerator, road pavement, curtain, wallpaper and artificial plant with self-cleaning properties. EnH titanium dioxide is a technology which reacts to not only UV light but also visible light.

Principle of photocatalyst

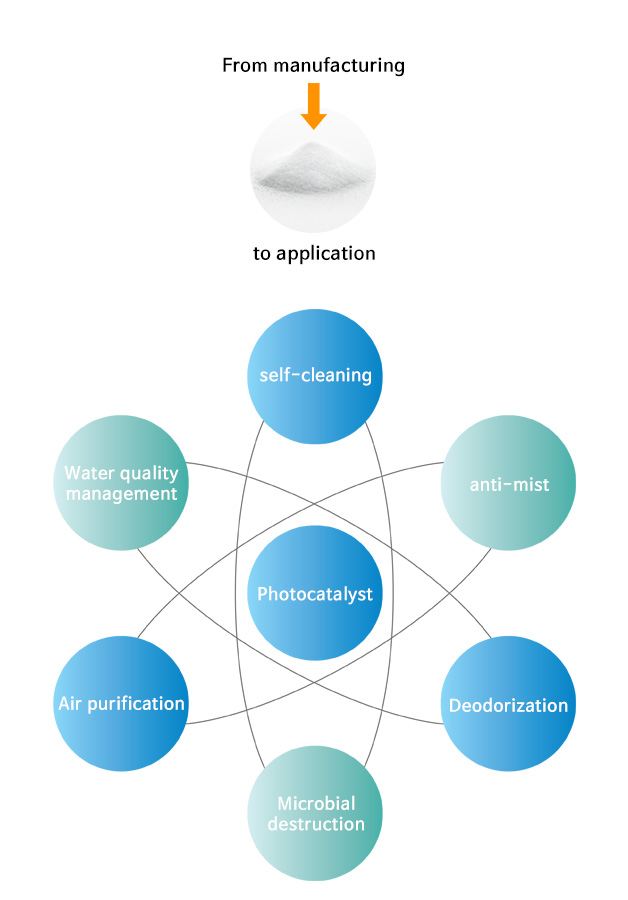

Photocatalyst Applications

-

Deodorization

- Reservoir

-Sanitary ware (toilet/tub)

-tile -

Outside building materials

-Building, Concrete, Glass

-Front cover: paint, ceramic

-

Building interior materials

-Window

-Indoor Coating

-Plastic tarpaulins -

Automobile

-In-vehicle / external mirror

-Deodorization

-Interior material

-

Interior materials

-light

-Curtains, wallpaper

-Ceiling, flooring

-

Home Appliances

-Air cleaner

-Refrigerator

-

Beauty

-Cosmetics

-Tooth whitening

-

healthcare

-Hospital Prevention Control

-Hygiene at home and work

-

City highway

-Packaging materials, road cleaning

-Tunnel lighting

-Air separator

-

- Secondary Battery Material

Conventional photocatalyst manufacturing technology

| Vaporization | Liquification | |

|---|---|---|

| Outline | Filtered titanium tetrachloride solution is sprayed with oxygen at a high-temperature (800~1000℃) oxygen atmosphere to oxidize titanium tetrachloride and produce titanium chloride particles. | A titanium chloride precursor having a hydroxyl group was prepared, The titanium oxide precursor thus prepared is heat-treated to produce titanium oxide particles. |

| Advantages |

Mass production possible, No organic solvent used |

Easy secondary processing Compared to meteorology, relatively low-temperature synthesis is possible. |

| Disadvantages |

Secondary processing is difficult to process with various products to meet the purpose. Poor dispersibility |

Use a large amount of organic solvents. High temperature heat treatment above 500°C is required to obtain titanium oxide. Variation of heat treatment crystallization patterns and degradation of photo catalyst activity. Difficult to clean and disperse. Difficulty in mass production. |

Properties of EnH Photo Catalyst

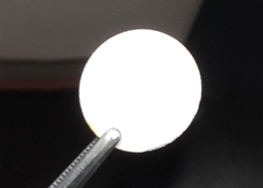

- • It is a solution synthesizing processing based on self-assembly (new titanium oxide production based on CO₂ nano bubble template) and one pot process capable of mass production in an eco-friendly manner, and it is characterized by its simple hollow structure and the high light penetration rate which induces photo-chemical reaction.

- • It is also capable of producing various product forms which allow the application of slurry, powder, paste, pellet and bids.

- • It is a 100% solution synthesis and cold synthesis method below 100℃, and it is also eco-friendly process (green chemistry) which does not use organic solvents.

- • It is capable of the world’s first synthesis of hollow structure using CO₂ Nano Bubbles, and it is easy to control microstructure, porosity, and porosity. It is a high-surface material with hundreds of㎡/g.

- • It can mass produce without large equipment leading to less initial investment.

Air Purification Performance Comparison with Products Registered under the Japanese Photo Catalyst Association (as of July 2017, 99 products from 40 companies)

Toluene

| 製品名 | 性能(μmol/h) |

|---|---|

| S Company | 1.5 |

| EnH(多孔質) | 1.15 |

Formaldehyde

| 製品名 | 性能(μmol/h) |

|---|---|

| EnH(多孔質) | 4.67 |

| W Company | 2.20 |

Acetaldehyde

| 製品名 | 性能(μmol/h) |

|---|---|

| EnH(多孔質) | 9.97 |

| B Company | 6.7 |

| S Company | 6.7 |

NOx

| 製品名 | 性能(μmol/h) |

|---|---|

| H Company | 11.36 |

| P Company | 4.62 |

| EnH(多孔質) | 0.97 |

Photo Catalyst Form

한국어

한국어 ENGLISH

ENGLISH 日本語

日本語